CAUTION: DAYLIGHT DRIVE SYSTEMS MUST BE DESIGNED AND BUILT BY A QUALIFIED ELECTRICIAN. IMPROPER WIRING AT HIGH VOLTAGES CAN CAUSE ELECTROCUTION OR START A FIRE.

Introduction to Direct Drive, AKA Daylight Drive

AC vs DC

Our lives are standardized to alternating current (AC) electricity because centralized power production and long distance transmission is more economical with AC than it is with DC. For a community scale microgrid, there is no inherent advantage to AC, and in fact there are many advantages to using DC. Solar panels and batteries produce DC, not AC, so a DC solar system can be simpler, cheaper and more resilient than a solar system that uses AC, simply because no inverter is needed.

However, there are advantages to direct drive DC beyond the omission of the inverter. (With direct drive, not only is the inverter removed from the circuit, but also the battery: PV panels are connected directly to loads.) The real magic of direct drive is the flexibility of the loads in response to changing electrical conditions. Direct drive DC motors operate on a fluctuating power supply. They speed up and slow down as the voltage changes on the circuit. This cannot be done with AC motors, it would destroy them. A direct drive circuit, however, can be underpowered or overloaded. A power supply of 1kW, fors operate on a fluor example, may simultaneously operate several DC appliances that have a combined load of over 3kW. The motors might slow down as they share the power, but useful work is done by all of the appliances.

An AC-based system has nothing approaching this level of flexibility. AC solar systems must be over-built with reserve capacity to ensure that all loads receive full voltage at all times. Orders of magnitude more hardware, electronics, complexity, and resources are required to run AC equipment with solar, compared to using direct drive.

Another advantage of direct drive over AC-based solar is that direct drive provides the user with real-time feedback on the availability of solar energy, allowing them to adjust their energy use as needed. An AC solar system, power output is either 120V or nothing, with no gradients in between. It’s easy for users to overdrain the battery bank without realizing it, which is bad for the battery and also means that eventually the inverter will shut off, leaving no power even for small loads.

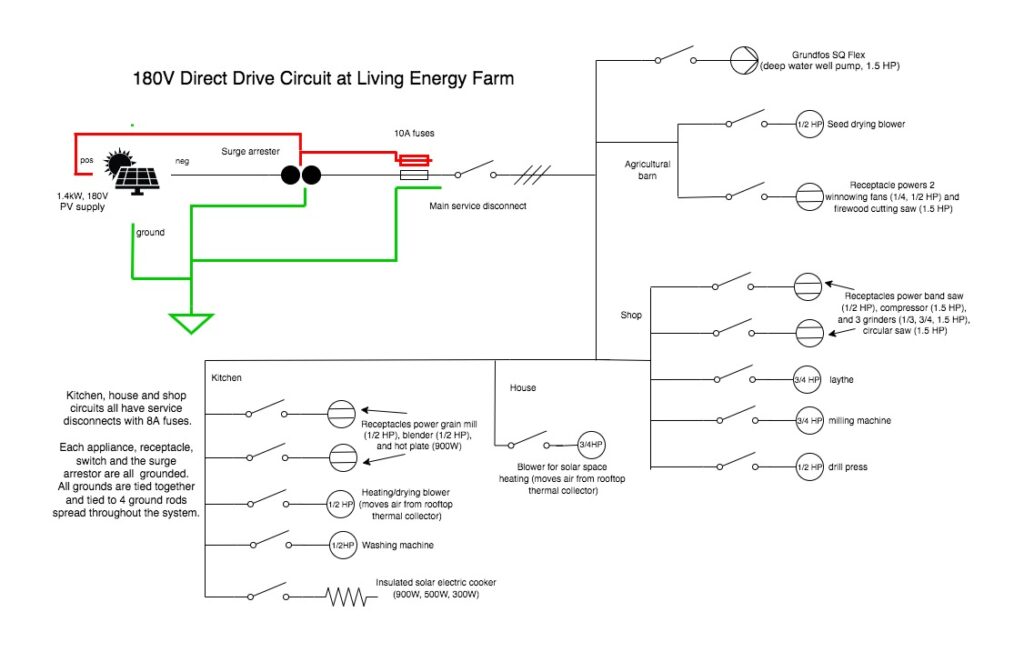

The most developed direct drive circuit that we know if is at Living Energy Farm. Below is a wiring diagram that shows all the loads on the circuit.

Because voltage and wiring requirements are different, a daylight drive system must be wired separately from a battery system. We highly recommend a dedicated PV supply for daylight drive.

Because daylight drive appliances only run when the sun is shining, work must be done during the day, or alternative energy storage (like thermal storage, or pressurized water) must be used to provide services at night and during cloudy spells.

High vs Low Voltage for Direct Drive

At LEF we have pushed the concept of direct drive further than anyone we know of, but we are not the only ones who thought to skip the inverter and power everything DC. There was a movement in the 80s and 90s to build “DC houses,” but these all ran at low voltages. Today, RVers are creating demand for 12V DC appliances again. While this is helpful in improving the supply chains for 12VDC equipment, there are a few issues with these systems. One is that these systems are still based on battery consumption, instead of non-electric storage and learning to use energy when it’s available. Another issue is that these systems are typically using low voltages, even for heavy loads. At low voltages, much bigger wires are needed, and appliance performance often is poor.

Arguably, the single most important discovery we have made at LEF is that is works very well to run many high voltage DC loads on a shared PV supply. For heavy loads like water pumps, kitchen appliances, washing machines and power tools, we recommend a target voltage of either 90 – 120 volts or 180 – 200 volts. A 90 volt setup is usually 3 panels in series, possibly in parallel with 3 more panels in series. A 180 volt setup would likely involve 6 panels in series.

Most household appliances are in the range of a couple hundred watts up to 1500 watts or so. At LEF we have a 1400 watt, 180 volt system that has served us well. Most daylight drive circuits we have built for other people have been a similar wattage, but wired at 90V. A minimalist daylight drive system of 3 panels in series (half the wattage) would work for many smaller motors. A nominal 90 volt PV rack would allow you to run 90 volt industrial brush motors as well as

some (modified!) household appliances made for 120 volts AC. The standard for AC electricity in Europe and Asia is 220 volt AC. Converted European/Asian appliances will run on a nominal 180V direct drive system.

For some commercially made solar direct appliances- like refrigerators- it’s not possible to use higher voltages, because the maximum voltage tolerance of the device is too low. For the Sunstar fridge, it’s 45V. For these, we recommend using a single dedicated solar panel, or two in parallel. Because the compressor only draws 80W, voltage drop is low, and wire size can still be small.

What runs direct drive?

Proceed with caution as most electrical and electronic equipment CAN NOT be powered by unregulated direct current (AKA direct drive). There are four main categories of appliances (that we know of) that CAN run solar direct.

- Appliances manufactured specifically for direct drive, AKA solar direct. The first choice for beginners. This category includes water pumps, refrigerators, cookers, ventilation fans, and minisplits. Always confirm that the manufacturer specifies the product can run solar direct- without batteries or voltage stabilization. “DC” or “solar” in the description does not mean it can run direct drive.

- Permanent magnet DC motors. Commonly used in industry, these motors are simple, robust, and repairable. They do have brushes that need to be inspected and replaced periodically- about once per year. Using belts and pulleys, we use these motors to power a variety of equipment on our farm. These motors can be found at 12, 24, 48, 90, and 180 volts. Leeson and Baldor are American brands that are good quality.

- Converted household appliances that have universal motors or brushless DC motors with rectifiers. “Universal” in this case means that a motor can run AC or DC. Many smaller household appliances have universal motors, or may even have brushless DC motors wired with rectifiers. (A rectifier turns AC into DC, like an inverter in reverse.) Appliances we have found in this category include: a variety of kitchen appliances like blenders, hand mixers and coffee grinders; vacuum cleaners, lawn mowers, and many power tools. These appliances require modification to run solar direct, which will damage the switch or rectifier of an unmodified appliance.

- Nichrome heating elements. These are used in water heaters, electric (non-induction) stoves, kettles, etc. Nichrome is a resistor that works the same on AC or DC, but draws a LOT of power. We use nichrome heating elements in our ISECs (insulated solar electric cookers). While it’s possible to convert a hot plate or electric water heater to solar direct, it is very inefficient and we generally advise against it.

What About When it’s Cloudy??

During a cloudy spell, a DC Microgrid slows, but it doesn’t stop. High voltage motors have very good performance even in clouds. You may need to reduce the total number of motors you can run under overcast skies, but you can still get work done. At LEF, we have a 1.4kW (about 2 horsepower) solar array. Any motor less than 1.5 horsepower will run just fine on a cloudy day. For the biggest motors on the farm, we wait for sunshine.

For essential services, like water pumping and refrigeration, the system must be designed to coast through cloudy spells. There are a few ways to do this:

- Increase PV supply. For example, the Sunstar fridge only needs 80 watts to run, however, a 400W panel might be required to supply 80 watts in overcast conditions.

- If you live in a cloudy climate, choose a positive displacement (helical rotor) water pump, which will continue to supply pressure even at low power input.

- Increase your use of non-electric storage. Install more storage tanks for water, or use more thermal mass (like water jugs) in your fridge to maintain temperatures.

Cooking with Direct Drive

Cooking takes a LOT of energy. While hotplates can be converted to run daylight drive, the best way to use daylight drive for cooking is with ISECs (Insulated Solar Electric Cookers) like the Roxy Oven. The insulation allows you to leverage your wattage into more heat, meaning you can do more cooking with less PV, and in less than ideal conditions.

For reference, a typical electric range uses 5,000-10,000 watts. A single burner, or hot plate, might use 1,500 watts. Our stand-alone Roxy oven, by contrast, is designed to cook with 300 watts. It works great, but it cooks slowly, like a crockpot. (In persistent clouds, it doesn’t cook at all.)

Another option is to use a higher power ISEC as part of an integrated daylight drive system where a PV supply is shared with many other appliances. At Living Energy Farm our high power Roxy Oven has two power settings: high (800w), and low (400w). It is powered by a high voltage 1.4kW system that delivers good performance even in clouds. While running the cooker on its high setting may impact other loads on the circuit, it works fine to run the cooker on low while simultaneously running other high wattage appliances, including our water pump, heating blowers, shop tools, etc. Often we turn off other loads and “pre-heat” the oven on high, then turn it down to low. The insulation maintains cooking temperatures, and power is made available for other appliances.

Wiring, Switches, Breakers and Grounding

Once again, DAYLIGHT DRIVE SYSTEMS MUST BE DESIGNED AND BUILT BY A QUALIFIED ELECTRICIAN. IMPROPER WIRING AT HIGH VOLTAGES CAN CAUSE ELECTROCUTION OR START A FIRE.

A 90V daylight drive system should be wired to code in a similar fashion as 120V AC system in terms of grounding, wire sizing, and boxes. DC systems use different breakers than AC systems. DC systems also need different switches. DC tends to arc across weak connections much more than AC. This can result in weak connections corroding more quickly with DC. It also means that DC power can quickly corrode the contacts on lightweight switches. Much heavier switches are required for high voltage DC than high voltage AC when powering heavy loads. For lights that use little power, AC switches work fine for DC.

Some DC appliances, like refrigerators, have electronic controls that can be damaged by a surge during a thunderstorm. We recommend protecting these devices with a surge arrestor. Quality surge arrestors for solar applications are available through Midnite Solar and Delta.